- Robot automatic infeed, increase the efficiency.

- Automatic pouring the fruit onto the brush avoiding the damage.

- Remove the fluff,sorting by shape and color,Ensure consistent appearance and quality.

Reemoon kiwifruit sorting solution is designed according to the characteristics of kiwifruit's fragile and easy to get damaged , the whole process of flexible operation, to avoid fruit damage throughout the process. Also sorting by diameter and weight.

料.png)

Robot feeding

Reemoon robot depalletizing adopts a fully automated processing system, and the robot arm automatically, quickly, continuously and flexibly pours fruit.

clamp type depalletizing

Palletizer with automatic feeding, equipted automatic fault alarm device, automatic head lifting position able to be controlled by encoder sensor.

C-Type bin tipper

The 180°rotation of the tumbler separates the kiwifruit from the fruit basket, and the kiwifruit enters into the feeding with a flexible belt, which protects the fruit and avoids hurting the fruit.

Remove the fluff

The brushes are driven by a chain driven by a motor, the brushes absorb the fluff on the surface of the kiwifruit, and the centrifugal fan extracts the fluff and attached debris from the brushes.

Weight sorting

Reemoon's weight sorting equipment adopts multi-point sensing contact and automatically measures the weight of boxes according to the standard kiwifruit sorting grade to ensure the consistency of the weight of each box.

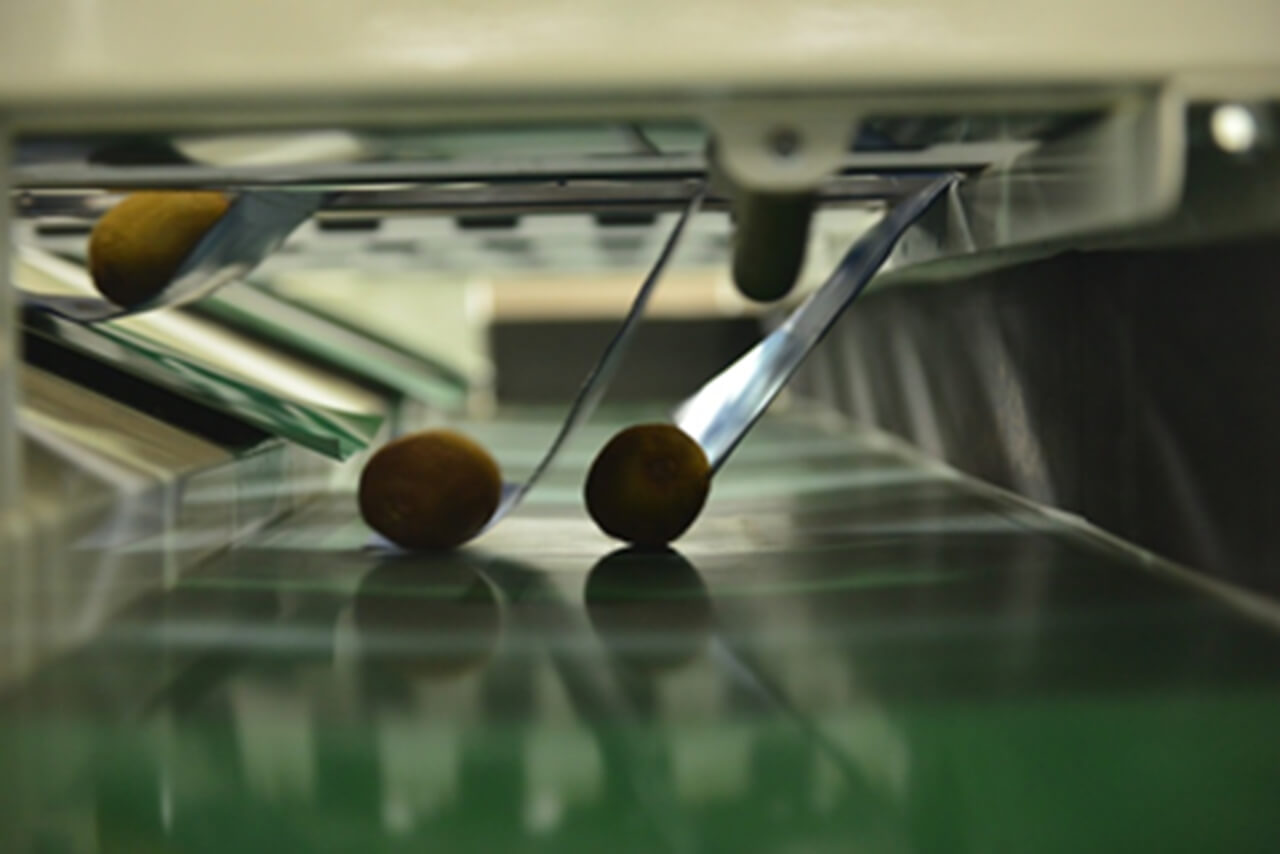

Kiwifruit diameter and shape sorting

The kiwifruit sizer checks the size of kiwifruit by calculating parameters such as the external dimensions and the projected area of the fruit, and allows the user to set parameters such as the diameter range and the aspect ratio of the fruit.

Chain Flapper Unload the fruit

By using the chain flapper to unload the fruit flexibly to avoid kiwifruit being knocked or bruised and let it land gently.

Brush unload the fruit

The outlet is equipped with a soft brush to reduce the impact of falling kiwifruit and reduce bruising.

Automatic Flexible craft filling

The empty crate is conveyed to the exit by conveyor belt, the rotating device raises the empty crate to the fruit dropping position, the rotating belt conveys the fruit to the empty crate, and the rotating device slowly decreases as the fruit quantity increases until it reaches the set target weight.

.png)

From the inputting of kiwifruit information to the sorting and processing of all data and packaging out of the warehouse, all data from picking to sales are inputted, backed up and tracked to achieve the effect of control and follow-up of the products.