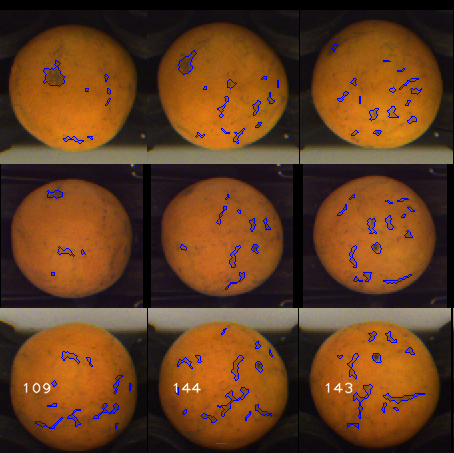

- Customized blemish standards, no blind spots in all-round photography.

- Brix is strictly graded to ensure the stability of internal quality.

- Customizable solutions provide customers with value-added services.

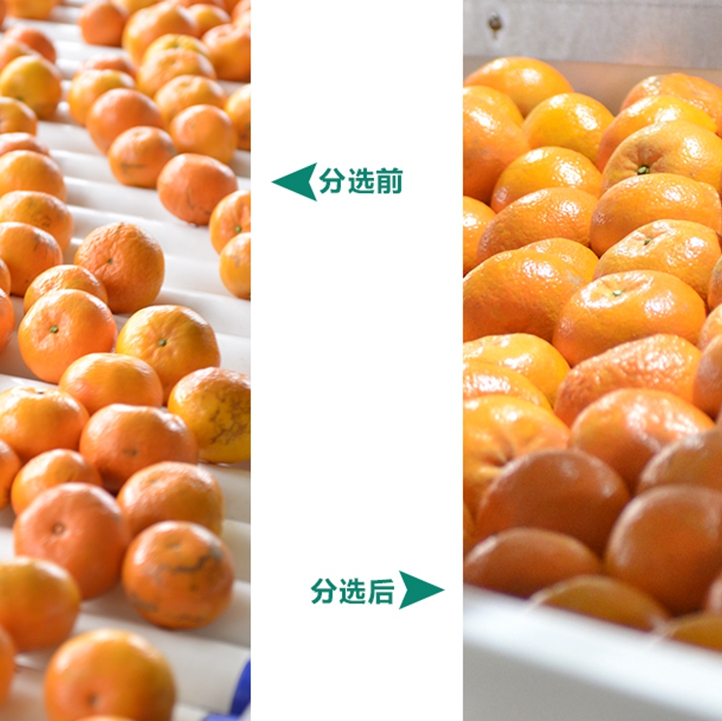

Reemoon’s mandarin sorting solution is suitable for even thin-skinned mandarins. It sorts by qualities such as color, size, blemishes and Brix.

料.png)

Robot feeding

Reemoon robot depalletizing adopts a fully automated processing system, and the robot arm automatically, quickly, continuously and flexibly pours fruit.

C type continuous box turning machine

Flexible fruit tipping with minimal damage. Empty frames are automatically processed and sterilized.

Side tilt box machine

After the robot arm automatically loads the material, the fruit frame is conveyed to the material inlet side and the fruit is overturned. The fruit is conveyed to the sorting line by the roller, and the empty frame enters the recycling system.

Bubbling cleaning

Water blasted bubbles quickly cleans the fruit and reduces fruit handling.

Hot Water Treatment

Treating mandarins with hot water at a set temperature and time period promotes disease and stress resistance of the fruit and extends its shelf life.

Water sterilization system

Uses broad-spectrum sterilization including bactericide and fungicide which sanitises the fruit and prevents rot and mildew.

Hot drying treatment

Dries mandarins with a hot air cycle.

Color sorting

Sorts mandarins into 16 color grades. Fine grading ensures fruit stability quality.

Size sorting

Calculates size and projected area of mandarin to ensure uniformity of the mandarin in size. Customizable size standard sorting.

Weight sorting

Automatically measures and weighs fruit to ensure the consistency of each carton weight.

Blemish sorting

Reemoon's self-developed technology is used to sort and grade the blemishes in the surface of mandarin. Using a distributed system, the sorting procedure does not depend on the computer, even if the computer is turned off, it will not affect the sorting at all. Greatly improve the efficiency of sorting and increase the sales value of mandarin.

Internal quality sorting

Automatically scans and detects internal qualities without cutting the fruit, resulting in a more consistent taste.

性化包裝.png)

Auto-filling packing

Automatic process removes the need for manual weighing and packaging, improving production efficiency.

.png)

Mandarin information from the sorting line is stored and backed up,allowing tracking and control of produce.